In 1800, no country in the world had an average life expectancy over 40. The global average was 29 years old.

Today, no country in the world has an average life expectancy under 53. The global average is 70 years old.

If you play indicator roulette across any metric of survival, access, or optionality, the world has gotten unequivocally better.

Why and how?

Our incredible human progress has been accelerated by technology, with an underlying motivation: how do we democratize life? Our strides to feed everyone, house everyone, educate everyone, and so forth have pushed the bounds of technology — a necessary tool to meet demand. Reaching new feats of quality of life, we can now ask more intricate questions. How do we feed everyone without animals? How do we create a vaccine for cancer? How do we build flood-resistant houses?

Humanity’s progress inspires me.

My optimism, energy, and happiness are derived from two words. They’re the blueprint for my ambition. They’re a nod to the slavic hospitality that raised me. They’re my mission statement for my micro and macro impact — how I host people in my apartment and how I think about contributing to society. When I am lost, feeding everyone are the two words I return to.

This is a work of gratitude, an exploration of the industrial revolution, and the basis for how I will lead my life. With warmth, helpfulness, global perspective, technological optimism, and love.

This is also the often-invisible story of fertilizer and the industrial revolution. It is a case-study for the improved basis of our lives. It is the long history and rationale behind the question I will continue living my life by: is everyone fed?

I originally wrote this essay for EATS 101, a senior honours seminar at the University of North Carolina unlike any education I’d had before. Mechanically, EATS was 15-20 hours of weekly reading and discussion over food and wine cooked by Dr.Jim Ferguson in a cohort of 14 curious souls.

We had the opportunity to welcome guests from around the world, travel to France, and to explore topics of ritual, nutrition, home, happiness, health, family and more. The only assignment was to craft a piece of food-related work. Quadrupling the minimal page count for our deliverable, I wrote this essay. It was originally supposed to be an exploration of Fertilizer supply chains, but instead and accidentally, I discovered and wrote the extended version of my life’s guiding force.Tragically, Dr.Jim Ferguson passed away on January 28th, 2025; I am honoured to have been part of his last and 43rd cohort of EATS 101.

One of my earliest memories is in the basement of an outlet mall in Mississauga, Ontario, Canada. It was cold and mid-winter and the floor of the mall was wet from all the slush on people’s boots. The fluorescent lighting was a good effort to combat the 4pm sunsets. And yet, it was about to be the most perfect day. We were going to eat something magnificent: a Cinnabon Nutella Cinnamon Roll. My mom and I split the monstrosity and we laughed because Nutella was getting everywhere and we smiled because the bun was warming us from the inside-out. What I remember most was seeing my mom happy, probably because I was happy, sharing our dessert.

While my first thought was yummy and hers was odlično, we radiated the same joy. The Nutella melted the same. The cinnamon still complimented the cardamom. My mom and I do not share the same mother tongue, but I’ve learned as her daughter that the most important things in life go beyond words. In a moment of profound appreciation over a $6 bakery chain cinnamon bun, I got to see my mom, who I knew as the woman who fed me and everyone I loved, finally feeding herself.

My mom trained me to derive happiness from serving other people. She showed me that a cinnamon bun shared tastes better. She is the reason I think in actions, not words. She is also the reason I cannot cook for one. When I cook, I immediately start thinking about how simple it would be to double and triple and quadruple the recipe. During university, I was perhaps most well-known for the elaborate dinner spreads in my living room, far removed from any concept of simplicity.

Food is a language of love that can replace words. I saw my mom turn our kitchen into an industrial baklava factory to love on our community during times where words fell short: marriage, graduation, immigration, birth, and death. No matter what happens, people will always need food. No matter what language someone speaks, how much money they have, their story, their mistakes, their regrets, their aspirations, people will always need food. We can always start with food.

During my last semester of university, when I started writing this essay, the Chapel Hill community lost Brook Cheuvront, a girl whose positivity, optimism and kindness was infectious. At the funeral service in Western North Carolina, I saw Brook’s community come together to feed everyone, spearheaded by her loving and grieving mother. Our mothers—born and raised in mountains 8,000 km apart — share the same instinct of love. And nourishing the people they love. I am grateful to have known Brook, and I am continually inspired to carry on her uplifting spirit.

Reflecting on my time living in Thailand, Singapore, Malaysia, Burundi, and Denmark, on paper, they seem so different from Canada or North Carolina or New York. And yet mothers everywhere have the same instinct. Culture, religion, politics, etc., may vary, but in all these places I have carved a home in, there was kindness, there was love, and there was always someone who cared about feeding everyone. As I have visited different and disparate places, I have realized that inside we are all the same.

As I have travelled and witnessed the universal drive to nourish, I have come to understand that feeding everyone requires more than goodwill; it demands infrastructure, resources, and strategic coordination. While sharing a meal may be instinctual, sustaining global food supplies is complex in design. This essay explores the philosophy, infrastructure, and invisible foundations of the food system from a technological perspective, with a lens on fertilizer. I hope to uncover some of the global strategy needed to feed everyone.

This paper is inspired by my mom who built a life how she makes her bread: from scratch, with love. And my dad, her incredible life partner, a vegetarian engineer, and a natural contrarian, who taught me to never stop questioning the status quo. I am profoundly grateful for the life my parents enabled for me and my brother in Canada. I am thankful for my dad’s praises of my ambition and my mom’s praises of my kindness. They have taught me to have faith in good people and technology. While this essay is my final piece of work at The University of North Carolina, I see it more of a launchpad for the rest of my life’s work: crafting societal infrastructure that ultimately feeds everyone.

Techno-Optimism

“I didn’t invent the language or mathematics I used. I make little of my own food, none of my own clothes. Everything I do depends on other members of our species and the shoulders that we stand on. And a lot of us want to contribute something back to our species and to add something to the flow. It’s about trying to express something in the only way that most of us know how because we can’t write Bob Dylan songs or Tom Stoppard plays. We try to use the talents we do have to express our deep feelings, to show our appreciation of all the contributions that came before us, and to add something to that flow. That’s what has driven me” — Steve Jobs [1]

The making of modern society is a story of collective leverage. Our collective leverage is fuel for the fact that we do not grow our own food nor sew our own clothes. Instead, society is collaborative: built on the exchange of goods and services, and the division and specialization of labour. We do not have to be self-sustaining agrarians in modernity. We can code, write, analyze, prescribe, paint, design, craft, cook, compute, imagine, execute, calculate, or any specialized action, in exchange for anything else we might need. We have a global marketplace to enjoy the produce of farmers, the medical knowledge of doctors, investment advice of bankers, etc. Technological infrastructure exponentiates this leverage [2,3].

The origins of the word technology come from the Greek word tekhnologia, meaning the ‘systematic treatment of an art, craft, or technique’ [4]. Society has been seismically impacted by the onset of technologies: the wheel enabled trade and transportation; the printing press democratized knowledge; the steam engine powered industry and reshaped economies; fertilizer fed half the world; the internet collapsed the barrier of distance and enabled a global marketplace of ideas and commerce. Each breakthrough has shifted the boundaries of what we could achieve. Better, faster, cheaper, more accessible, distributed, and prevalent. Technology pushes forth our collective leverage and re-invents societal infrastructure.

In 1850, the average global life expectancy was 29.2 years old. Today, it is 70.1 years old [5]. In 1850, a newborn in the United Kingdom had a 24.7% chance of dying before the age of five. Today, that number is 0.4% [6]. In 1850, 73.81% of people were in extreme poverty; today that figure is 10.01% [7]. The progress of humanity, the more than doubling of life-expectancy, a 62-fold reduction in infant mortality [8], and 7-fold reduction in poverty, are a couple of indicators that support the truly extraordinary and exemplary times we get to exist in. The top cause of death in 1915 was infection; 100 years later in 2015 it was cancer or heart conditions [9]. Today we have sanitation, vaccines, democracies, clean water, refrigeration, electricity, and infinite interventions unfathomable to even the royalty of the 18th century. We live beyond the means of history’s kings with air conditioning, running water, motorized transportation, abundant food, life-saving medical equipment, flush toilets, hot showers, eyeglasses, aspirin, books, instantaneous global communication, full-stocked grocery stores, oral hygiene, and many more exceptional things we take for granted everyday. The future is inventable [10], in particular with technology. Within the means of these facts I am extraordinary optimistic. Technology has, and will continue to, reimagine the quality of life for human beings around the world.

The Industrial Revolution transitioned society from rural and agrarian to urban and mechanized. The First Industrial Revolution (1760-1840) [11] was enabled by an abundance of energy (coal) that could power steam engines, which could go on to to power machinery in factories, locomotives for trains, and equipment in mines. Advances in iron production (blast furnaces fueled by coal) enabled the construction of the railways and machinery, which built the foundation for a more advanced transportation network (with rail and canal systems), and a mechanized factory system with improved productivity and output.

The First Industrial Revolution is not something that abruptly started and ended. Following the 1840s, the innovations “transitioned” and sprawled around the world. Similar to the William Gibson quote: “The future is already here. It’s just not evenly distributed yet” — there was a scale-up period.

For instance, rail emerged as both a product and a solution from the first industrial revolution. Iron was used to build rail infrastructure and rail infrastructure was used to transport iron to build other things. Coal was used to power the steam engines of the locomotives, and rail was used to transport coal to power other steam engines. It was a positive feedback loop that kept building and reinforcing upon itself. For instance, during the mid-19th century, the US railroad saw massive expansions, pictured below [12]. The fruits of the First Industrial Revolution transitioned society, upgrading our infrastructure to include the transportation, manufacturing, and economic practices that laid strong foundations for the Second Industrial Revolution.

The Second Industrial Revolution (1870 - 1914) [13] was defined by the mass-production of steel, electricity, the invention of the automobile, oil refining, and the development of the chemical industry. Thanks to the invention of the Bessemer Converter [14] (a type of blast furnace), we had cheap, mass-produced steel that meant we could build larger bridges, longer and more durable railroads, ships, cables, broilers, engines, tanks, guns, and other machinery or infrastructure [15]. Railroads became a global phenomenon, our ability to refine oil lent itself to the internal combustion engine later used in cars, cables lined the ocean (pictured below) to build the skeleton of the telegraph system, enabling intercontinental communication [16].

The important consequence of industrialization was urbanization. The promise was simple: instead of outdoor, physically demanding work for sustenance, one could have a pre-determined workday, earn a wage, buy necessary items, have their children go to school; instead of a life swayed by the weather. It was a less uncertain life. People flocked from rural farm lifestyles to the cities for urbanized guarantee. Human societies reached an unprecedented density, which gave rise to new problems from overcrowding. Hence, we had to invent modern sanitation practices, sewage systems, hospitals, and clean water treatment. People’s children did not need to become farmers, so we invented public education, and we used the printing press (a product of the Industrial Revolution) to mass-produce books. People, worked together in large batches, and thus came the rise of labour movements, unions, and labour laws. Steamships and railroads reduced shipping times and costs, while innovations like the telegraph enabled faster communication between trading partners. Industrialized nations sought raw materials from colonies and exported manufactured goods, creating a global supply chain.

The industrial revolution modernized industries and society. A consequence of the revolution was improved living conditions. Public health conditions grew dire with overcrowding which forced the invention of strategic innovations like vaccinations, antiseptics, clean water, sewage systems, etc., which dramatically reduced deaths, particularly from infectious diseases. Farmers had access to technological tools (e.g., seed drills, threshers, etc.) [17] that enabled greater labour efficiency, meaning fewer workers were needed on the fields; these workers were free to pursue the boom of careers in urban areas. The reduction of labour costs trickled to a reduction of food costs, and furthermore, the access to railways and steamships reduced the cost of transporting food; families, and particularly children, had reliable, affordable access to food. This intervention contributed to increased life expectancy. Fewer people needed to work the fields, so they went to the cities where they could live better with more stable incomes; by 1851, for the first time in British history, more people lived in the city than in the countryside [18]. The net result: people lived longer lives.

While people died older, the birth rate remained relatively stable (England statistics: 4.51 children per woman in 1840, 3.9 in 1890) [19]. The net result was a population boom, in parallel with a gross domestic product (GDP) boom:

With a booming population, how do we feed everyone?

History

The Quarrel

The Malthusian Trap (pictured below) [20], proposed by Thomas Malthus, argues that population grows exponentially while food production increases only arithmetically, inevitably leading to famine and poverty. Malthus dismissed technological progress, believing innovation could not overcome the limits of natural resources. He would be blown away by the billions of people and their quality of life on earth today!

As quality of life improved, people lived longer, and Malthus was right: we needed more food. However, where Malthus underestimated humanity was in our ingenuity and production capability. Quality of life rose to heights unimaginable to previous generations, and the same sense of awe—almost magical in its transformation—applied to our agricultural practices. Farmers shifted from methods rooted in centuries of tradition to innovations that harnessed science and engineering to multiply yields to unprecedented levels. These advances remind us how lucky we are to face the problems of abundance and rising demand, rather than persistent famine and scarcity.

The growth of the global middle class in countries like India and China exemplifies this transformation: as people enter this economic bracket, they gain access to a better diet, more education, and healthier lives. While this progress brings challenges, such as increased demand for more resource-intensive foods like meat and dairy [21], it also highlights a key opportunity: the chance to innovate solutions that support both sustainability and development. These challenges are markers of human progress and opportunities for engineering solutions that enhance both quality of life and societal resourcefulness.

The Nutrient (but especially nitrogen) Need

It is universally understood that plants need water and sunlight to grow. Plants also require three primary macronutrients: nitrogen (N), phosphorus (P) and potassium (K)[22]. Nitrogen and phosphorus are the key building blocks for the proteins, enzymes and chlorophyll that make up plants. Not to mention, they make up the backbone of genetic code (DNA). Without N and P, plants cannot produce the proteins they need for cell structure, nor can they make the chlorophyll required for photosynthesis, the process that converts sunlight into energy for growth [23]. K, on the other hand, plays critical roles in various physiological and biochemical processes like water retention, enzyme activation, stress tolerance, and maintaining electrochemical gradients within cells [24].

Of the macronutrients, N has historically been the limiting nutrient for plant growth. P and K are found in rock, and therefore the soil, but N has to be fixed from the atmosphere, which cannot be done by plants alone; they need nitrogen-fixing bacteria.

Although nitrogen gas (N2) is present in air, plants cannot use it directly in this form. It must first be converted into reactive forms like ammonia (NH₃) or nitrate (NO₃⁻). Bacteria in the soil can “fix” atmospheric nitrogen gas into forms that plants can uptake and use. Legumes (beans, peas, lentils, etc.) are especially effective in this role, forming symbiotic relationships with nitrogen-fixing Rhizobium bacteria in their roots, enriching the soil with nitrogen.

Historically, traditional methods to improve soil health focused on natural processes to replenish nitrogen. Practices like crop rotation [25] and intercropping with legumes, leveraged their ability to fix atmospheric nitrogen into the soil. Techniques like the Three Sisters combined corn, beans, and squash, where beans enriched the soil for the other crops [26]. Additionally, farmers used organic matter, including manure and compost to recycle the N, P, K, and other nutrients back into the soil. If we have traditional practices that work, why did we need synthetic fertilizer?

To understand this, we must appreciate the population boom and the industrial output metrics of farms.

Crop Yield and Guano (Bird Poop)

Crop yield, the amount of produce harvested per unit of land, became a central measure of productivity during the Industrial Revolution. Agricultural output referred to the total quantity of crops, livestock, and goods produced.

There are two ways to increase agricultural output: farm more land and or get more from the land farmed. With a growing number of mouths to feed, why would we not want more food from the same plot of land?

Farmers needed to solve the age-old nitrogen problem: how could they get more nitrogen into the soil?

In the arid climate of Peru, Guano (bird droppings) were rich in NPK. In the mid-1800s, North America and Europe would import Guano for use as fertilizer. This adoption of fertilizer “facilitated a departure from organic “closed systems” of farming, in which nitrogen is cycled among soil, plants, animals, and people at the local scale, toward “open,” energy-intensive approaches to agriculture”. Guano was a valuable resource “because they could be transferred swiftly and inexpensively from South America’s Pacific shores to the increasingly degraded soils of the Atlantic world”. It was valuable and it could be transported [27].

In 1840, Peru discovered the world’s largest supply of Guano off the southern Pacific coast, on the Chincha Islands [28]. The period in between the first and second Industrial Revolution (1840-1870) was the Guano boom [29]. During this period, European agriculture experienced a significant transformation due to the importation of Guano: the high nitrogen and phosphorus content of Guano enhanced soil fertility, leading to increased crop yields and supporting the growing populations of industrializing nations. The surge in Guano imports marked a pivotal shift towards more intensive farming practices in Europe [30].

As farmers recognized the utility, effectiveness, and business benefits of Guano, demand and prices rose in tandem. “In 1843, a shipload of Guano arrived in Baltimore and fetched $0.07 a ton. Seven years later, the price hit $76 per ton” [31]. With rising demand and a stagnant supply in a South American monopoly, the United States pursued price-stabilization measures to ensure their farmers could get the desirable agricultural inputs. This introduced the passage of the Guano Islands Act of 1856. The law now enabled the United States to privately conquer unclaimed Guano islands.

As luck would have it, while humans had the Industrial Revolution to instigate a population boom, birds did not. The world’s supply of bird droppings did not meet the world’s rising demand for fertilizer. This was concerning for everyone, but especially farmers who were getting used to a new precedent of crop yields. Farmers “watched corn and cotton yields triple, quintuple, or even decuple, thanks to a fertilizer that vastly outperformed cattle and hog manure” [32]. The productivity increase per acre was estimated at ~25% [33].

Thankfully, during the 19th century, rich deposits of sodium nitrate were discovered in South America’s Atacama Desert [35]. Dubbed “white gold,” this mineral offered a nitrogen source that was more abundant and easier to mine than Guano. It quickly became a lifeline for agriculture. The sodium nitrate deposits were so important that they motivated the War of the Pacific (1879-1884), a conflict primarily involving Chile, Bolivia, and Peru, over the control of the lucrative nitrate-rich lands in the Atacama Desert. The war ended with a decisive Chilean victory, leading to Chile’s annexation of vast territories previously belonging to Bolivia and Peru; and Bolivia becoming a landlocked country.

The demand for nitrates extended beyond agriculture into the production of explosives for industrial and military use. Notably, explosives had many industrial uses: “dynamite, discovered by Alfred Nobel, was used in the construction of tunnels, roads, oilwells, and quarries. If ever there was a labor-saving invention, this was it”. Of course, Chile’s nitrates played a crucial role in nitrate-based explosives for military purposes, too.

In the early 1900s, geopolitics in Europe were trending towards World War I and countries at war do not want to have the same explosives dealer! This threefold utility in agriculture, industry, and military, heightened the strategic importance of nitrate, and was the backdrop for German innovation.

Haber-Bosch

In the race to sustain a growing world, nitrogen became humanity’s most coveted element, fueling both farmlands and firepower. With natural sources of nitrogen running scarce, the Haber-Bosch process emerged as a lifeline, turning air into fertile ground and explosive potential — and altered global power dynamics.

Fritz Haber and Carl Bosch revolutionized agriculture and industry with the Haber-Bosch process, which synthesizes ammonia from atmospheric nitrogen and hydrogen. In 1909, Haber developed a method to convert atmospheric nitrogen into ammonia using a high temperature and high pressure environment with an iron catalyst. Bosch scaled it for industrial production, with the first industrial plant built in 1913 [37]. For enabling the arguably the most important chemical reaction in human history, Haber won the 1918 Nobel Prize which was awarded in 1919 due to WW1 [38].

“The fixation industries, although in existence at the outbreak of the war in 1914, received their first great development during the conflict, largely through the necessities of the Central Empires, then cut off from the natural nitrates of Chile” [39].

The breakthrough commodified nitrogen, offering more supply than demand, dropping the cost. Written in 1928: “There is no likelihood of the world starving to death because of lack of nitrogen; the starving is more likely to be on the part of the higher cost nitrogen producers, who cannot sell their products at a profit in an oversupplied market.” [41]

Guano supported the human derivatives of the industrial revolution. Nitrates replaced Guano in the 1870s. Chemically synthesized ammonia replaced sodium nitrate in the 1930s. We became industrially closer to feeding everyone. What next?

The Green Revolution (1966-1985)

In the mid-20th century [42], agronomist Norman Borlaug sought to develop a high-yield, disease-resistant wheat variety for Mexico to combat global hunger. The crops were introduced in India and Pakistan to combat the famines of the 1960s. The varieties of wheat he developed would go on to be a model for other staple crops [43].

His technique was to modify the plant itself. This agricultural transformation dramatically increased food production in developing nations, alleviating fears of a Malthusian collapse. This work in engineering higher yielding and more resilient crop varieties earned Borlaug the Nobel Peace Prize in 1970 [44]. He is often referred to as the “Father of the Green Revolution.”

The Green Revolution was a period of agricultural transformation during the 1960s, marked by the development and adoption of high-yield crop varieties (HYV), fertilizers, pesticides, and advanced irrigation methods. This shift led to significant increases in food production, particularly in developing countries, helping to alleviate hunger and to support rapidly growing populations. “After the green revolution, the production of cereal crops tripled with only a 30% increase in the land area cultivated” [45]. HYVs have increased crop yields by 44% between 1965 and 2010 [46]. Consequently, countries like India, Mexico, and Pakistan could self-sufficiently feed their population, instead of relying on imports [47].

The Green Revolution focused on cereals because they are staple crops that provide a significant portion of daily caloric intake for much of the world’s population. Cereals like wheat, maize and rice were particularly suited to the new high-yield crop varieties, which could thrive with the application of fertilizers, irrigation, and modern farming techniques, resulting in substantial increases in productivity.

The feat of the Green Revolution: while population, cereal production, and cereal yield grew by +150-250%, the land used for cereal remained constant. That meant we could feed everyone with less land per person [48].

The success of Borlaug's high-yield crops depended not only on genetic improvements but also on the availability of key agricultural inputs. These crops required intensive irrigation, large quantities of chemical fertilizers, and pesticides to achieve their full potential. This input-intensive approach, while highly effective in increasing yields, demanded significant infrastructure and financial investment. The Green Revolution's reliance on high inputs required significant capitalization costs, which often limited access to wealthier farmers and regions with better infrastructure; the nature of HYV excluded many small-scale and resource-poor farmers without access to government or external aid.

The Missing Green Revolution: Africa

While the Green Revolution resulted in leaps and strides for global food security, especially impacting economies like Mexico, Philippines, India and Brazil, there is a continent-sized exception to the trend: sub-Saharan Africa. Countries that adopted HYV and modern farming techniques experienced a boost productivity without expanding farmland. In contrast, Africa’s cereal production has grown because of expanded land-use, not yield improvements. A comparison of Population, Cereal Production, Yield, and Land-Use for India and Africa below [49].

Today, despite Africa containing >18% of the global population, the continent only accounts for 3-4% of total fertilizer consumption [50]. According to the 2023 Agricultural Commodity Clusters (ACC) survey, 59% of small-holder farmers surveyed said that affordability was the most significant barrier; an increase from 40% in 2019 [51]. Increased fertilizer availability was a key lever in the 1960s Green Revolution, and Africa has been missing out.

“Opposition to increasing fertilizer use in poor, low-productivity agricultural economies is a huge mistake. The use of fertilizer, modern crop varieties, irrigation, and mechanization has all but eliminated the scourge of famine. It is not a coincidence that most of the world’s food insecure countries practice non-industrial agriculture” [52]. Advocating for increased fertilizer use in low-productivity agricultural economies is essential to combating hunger and fostering food security.

The lack of fertilizer in Africa boils down to three parameters: (1) no domestic fertilizer production, (2) really expensive imports, with cumbersome supply chains, (3) no institutional support (e.g. subsidies, protection against price volatility). Without concurrent industrial infrastructure, transportation infrastructure, and strong managerial institutions, it is a chicken-egg problem for development even if the playbook is clear (fertilizers will improve crop yield: that is clear).

Subsequently, when disaster strikes it is those without the aforementioned infrastructure that will be disproportionally affected. For example, the Russia-Ukraine conflict caused fertilizer prices to hit record highs in 2022 [53]. In sub-Saharan Africa, fertilizer prices rose from $200-500 USD per tonne in 2021 to more than $1,000 per tonne USD in 2022. According to the IFDC, “The subsequent drop in fertilizers coming into Africa will result in decreased crop production equal to approximately 30 million metric tons of grain, a year’s food supply for 60–90 million people” [54]. A farmer in America or Europe will also struggle with a 2-5X increase in a key agricultural ingredient, but a farmer in the Global South does not have the same welfare states or democratic government subsidies to fall back on, and much less a Whole Foods or Farmer’s Market to sell organic produce at higher margins to upper-class customers.

The image below is from a paper the used network-based simulations to understand how external shocks to food systems affect average demand deficient (kcal/person/day)— the countries most drastically affected by shocks are not the Western, Educated, Industrialized, Rich, Democratized (WEIRD) ones [55].

In contrast, the many of the countries least affected by external shocks (figure above) are the ones who propagate the largest percent of their domestic shocks to other nations [56].

A lack of Africa’s internal fertilizer supply is partially due to limited natural gas resources, a key raw material. The figure below illustrates that no data [57] exists for much of Africa, besides the well-known Northern and Nigerian reserves of natural gas.

Additionally to natural gas, the high costs associated with establishing and operating fertilizer production facilities, coupled with limited access to financing, deter investment into the sector.

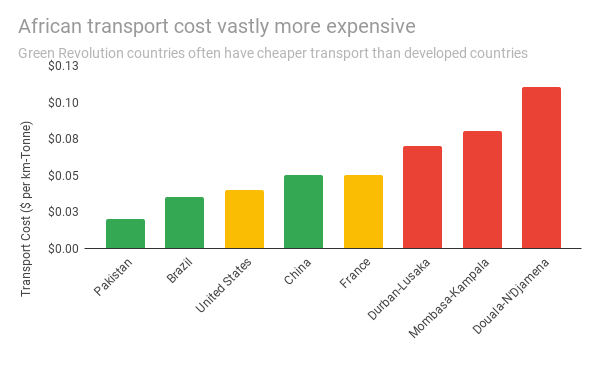

If fertilizer is not being produced, it needs to be imported; but fertilizer is expensive to import into Africa. Almost 40% of the cost comes from logistical (handling, sea transport, land transport), operational (e.g., salaries), and financial (duties and taxes) costs [58]. “Land transport in West Africa bears the highest cost in the fertilizer supply chain at an average of USD 0.07/tonne/km, compared to Europe which averages USD 0.03/tonne/km. This high cost is attributed to the competitiveness of the corridor and the distance between the port and the production area” [59]. High logistics costs, particularly for land-locked countries, bring the cost of fertilizer up. These expenses are passed to the farmer [60]. The two figures below detail the lack of rural roads and the high cost of transit within Africa compared to Green Revolution countries:

Overall, “fertilizer logistics, especially road transportation costs, constitute a significant component of fertilizer prices. This becomes even more important for landlocked countries dependent on their coastal neighbours” [61]. Six ports in East and Southern Africa serve 60% of the entire sub-Saharan Africa fertilizer market [62,63]. Transport costs account for ~30-40% for the final price of commodities (including fertilizer) traded intra-Africa, rising to ~60% for landlocked countries [64]. This concentrated port logistics system is vulnerable to disruptions and concatenated with poor road infrastructure (only ⅓ of rural Africans live within 2km of an all-season road) [65], they exacerbate inaccessibility to life-altering interventions like fertilizer, medicine [66], and construction materials [67].

Development requires a concurrent effort improving many things at once. Hence, strong institutions, particularly democratic ones, are beneficial to the roll out of technologies. For instance, Northern Nigeria has traditionally had more fertilizer subsidies from the government; despite being further from the coast (higher transport distance), the North has higher aggregate fertilizer use than the South. They have also cultivated a larger area of land with higher value crops [68]. Institutional support is critical to ease the transition into modern agriculture: “Fertilizers are very expensive, and in order for smallholder farmers in SSA to have access to fertilizers, the cost of fertilizers must be subsidized” [69].

Poor institutions can hinder in more ways that negligence. Their bureaucracy can also slow progress; time is money, which trickles costs to the consumer. For example, delays at the Kenya-Uganda border accounted for more time than driving the 1,100km from Mombasa, Kenya to Kampala, Uganda.

Like fertilizer, rice is a global commodity whose price is highly volatile due to weather dependency, export conditions, currency fluctuations, geopolitical tensions, cost of inputs (including fertilizer), etc. A study found that “institutional quality is found to exert a significant moderating influence on the interaction between volatility in the price of rice and inflationary conditions in SSA. The results suggest that effective regional or domestic institutions help negate the adverse effects of volatility in the price of rice on inflationary conditions among economies in the sub-region” [70]. Strong institutions play a crucial role in mitigating agricultural price volatility, which directly impacts food security and economic stability.

Sub-Saharan Africa’s exclusion from the Green Revolution’s agricultural leap forward, partially due to its lack of industrially revolutionary infrastructure, underscores the critical need for concurrent investments in infrastructure, transportation logistics, and strong institutions. Development is not a linear process—it requires simultaneous advancements in infrastructure, market systems, and institutional capacity. Without coordinated efforts to overcome these systemic barriers, Africa’s agricultural potential could remain underutilized, perpetuating cycles of food insecurity and economic instability.

What about the Environment?

It would be incomplete to mention the Green Revolution without acknowledging the environmental repercussions of wide-spread soil fertilization. Over-application of fertilization can have downstream environmental effects, like eutrophication [71]. There are a numerous papers and essays about this topic [72,73].

However, by coupling the industrial and environmental angles, it is clear that the crisply negative rhetoric of the mainstream fails to acknowledge the net-positive impacts of the Green Revolution. The straw-man argument of ‘nothing matters if there is no planet’ oversimplifies the issue, failing to account for the millions of lives saved and the socioeconomic benefits achieved through agricultural, and more broadly, industrial innovation. Judging the environmental impact of an activity, like farming, needs to be done with multiple parameters of consideration. For instance: land use, irrigation, downstream effects, and greenhouse gas emissions. When we measure against multiple axioms, the picture of pure negativity starts to get blurry. I will expand on the environmental impacts in the paragraph below, however, I emphasize that the solution is not reversing 200 years of industrial progress.

Chemical fertilizers, when used properly, can significantly increase crop yields on existing farmland, which reduces the need to clear forests and other natural ecosystems for agriculture [74,75,76]. By intensifying production on current agricultural land, fertilizers contribute to land sparing, where higher yields reduce pressure on forests and grasslands that act as carbon sinks. Only 60% of farmland is used to grow crops for consumption, the rest is used to feed animals (35%) or for industrial products (5%) [77]. Of the land that is farmed, most of the land is “far from maximum yield,” [78] as depicted in the figure below.

Building on the feats of modern agriculture, we know what works. While we should mitigate issues of excess, properly managed use of fertilizers and other mechanized farming interventions pose significant upside, particularly for the world’s lowest productivity plots of land: “Reducing yield gaps in the least productive agricultural lands may often require some additional fertilizer and water. Care will have to be taken to avoid unbridled irrigation and chemical use… To close the world’s yield gaps, we also must overcome serious economic and social challenges, including better distribution of fertilizer and seed varieties to farms in impoverished regions and improving access to global markets for many regions” [79].

The precise application of fertilizers can result in lower greenhouse gas emissions per unit of food produced compared to some organic farming methods. Precision methods like Enhanced Efficiency Fertilizers (EEFs), control the release of nutrients, minimizing the ‘unproductive’ use of fertilizer components like nitrogen [80]. Additionally, technologies, such as GPS-guided equipment and variable-rate application systems, enable farmers to apply fertilizers more accurately, ensuring that nutrients are delivered in the right amounts and at the optimal time for plant uptake [81].

In Florida, “the optimization of irrigation and fertilizer strategies can reduce irrigation by 48% and fertilizer application by 26% with the same yield” [82]. A paper exploring multi-objective algorithmic optimization of agricultural inputs found that their computed irrigation and fertilization strategy reduced water consumption by 44%, nitrogen application by 37%, and resulted in economic benefits of 7 to 8% [83].

The logic behind multi-variable optimization is each input could confound the effects of another input, and each input has diminishing returns. Therefore, there exists some optimal point where the variables are combined to maximize their effects. The figures below demonstrate the non-linear impact on yield for fertilizer and irrigation respectively. More is not necessarily better, but there is a point of high slope where more is better than less. The key-point is that technologies can amplify the collective leverage of current interventions [84]; that is, we should be optimistic because the future is inventable and there is room to optimize.

As a result, synthetic fertilizer (and industrial agriculture), can be environmentally superior to organic fertilizer. Greenhouse gas emissions from excessive organic matter decomposition occur in organic farms, which often rely on manure and compost [85,86]. In many cases, organic farming, which strictly prohibits the use of synthetic fertilizers, requires more land to produce the same yield, which could lead to greater land use changes and higher carbon footprints [87,88], in addition to the GHG emissions from organic matter decomposition.

When managed carefully, synthetic fertilizers can help maximize yields, lower the carbon intensity of food production, and support climate goals by allowing more land to remain in its natural state. There are benefits to eating organic food, however, from a comprehensive environmental perspective, reducing your environmental footprint is not one of them. This discrepancy between the environmental impacts of organic vs conventional agriculture will be further exacerbated as conventional agriculture embraces optimizing technologies to enhance their yields, minimizing land loss, key agricultural inputs, and energy use [89]. The figure below emphasizes this comparison:

However, when fertilizers are applied excessively or just before heavy rains, nutrients like nitrogen and phosphorus are often washed away from fields, entering rivers, lakes, and oceans where they contribute to issues such as harmful algal blooms, creating dead zones in aquatic areas [90].

However, runoff is not an inevitable outcome of fertilizer use; rather, it often results from mismanagement. With practices like precision agriculture, timing applications to avoid rainy periods, buffer zones, cover crops, conservation tillage [91] farmers can greatly reduce runoff risks [92]. This balanced approach allows for the use of fertilizers to boost crop yields and support food security, particularly in under-resourced regions, while minimizing environmental impacts.

Next for the Green Revolution

Billions of people owe their lives to synthetic nitrogen fertilizer. 50% of the global population is sustained by the availability of synthetic nitrogen [93] and crop yields would plummet in half without it [94]. Synthetic fertilizer has, and will continue to, feed everyone [95].

In summary, the Green Revolution introduced high-yield crop varieties, advanced irrigation, and chemical fertilizers, allowing developing countries to achieve unprecedented increases in food production and self-sufficiency without significant land-expansion. However, Africa was largely left out of this transformation; logistical barriers, such as the high cost of intercontinental transport, made it difficult to access these vital inputs. Consequently, while other regions saw rapid agricultural development, Africa’s growth remained constrained, highlighting the critical role of logistics and accessibility in the global distribution of resources essential for feeding the world.

We should not let “perfect” be the enemy of progress. Fertilizers have their repercussions, as do organic methods, but when it comes to feeding everyone, the food sources for 4 billion people exist because of NPK fertilizers. Half of the nitrogen cells in your body come from the Haber-Bosch process [96].

Fertilizers exemplify progress—they enable life and food security for billions, transforming agriculture to meet the demands of a growing global population. By embracing responsible innovation, we can continue to feed the world while working toward sustainable solutions. Technological adaption is humanity’s greatest tool. It is how we adapt to surpass previous pessimism, enabling better lives for billions.

Current

Ammonia - The Central Infrastructure

In ‘nature’, plants primarily obtain nitrogen from bacteria that convert atmospheric nitrogen gas (N2) into forms of nitrogen inside the soil that plants can use, like ammonium (NH₄⁺). These nitrogen-fixing bacteria are an essential intermediary since atmospheric nitrogen gas (N2) is unusable by plants. This is because there is an extremely stable triple bond holding the nitrogens together which is difficult and energy intensive to break; plants do not contain the cellular ‘machinery’ to break the bond [97]. As a result, N2 is a tight bound, chemically inert molecule that requires a significant amount of energy to break apart before it can react and recombine into other substances. In contrast, ammonium (NH₄⁺) has only single bonds and is less stable but much more reactive, making it readily available for plants to absorb and convert into essential molecules for growth [98].

Producing ammonium (NH₄⁺) is a two-step process for bacteria. First, they convert atmospheric nitrogen (N2) into ammonia (NH3). Nitrogenase enzymes [99] break the N2 triple bond, then add three hydrogens [100] to each nitrogen [101]. Second, the bacteria release the ammonia (NH3) into the soil which reacts with water to form ammonium (NH₄⁺), which plants then uptake.

The first step is called nitrogen fixation: atmospheric nitrogen is fixed into something more useful (ammonia (NH3)). The second step can be thought of as a processing step: since ammonium (NH₄⁺) is more stable and readily absorbed by plants, ammonia (NH3) is spontaneously converted to ammonium (NH₄⁺) in the presence of water [102]. Ammonia (NH3) is highly reactive — for instance attacking cellular structures — and therefore toxic, and thus, it is converted to ammonium (NH₄⁺) before it enters a plant [103].

This ‘natural’ process provides an important design scaffold: first, we must convert atmospheric nitrogen into ammonia, and then we need to process ammonia into something more biologically friendly (non-toxic) [104].

For most of history, the global nitrogen cycle was defined by these parameters: the air has an abundance of nitrogen, bacteria have the enzymatic machinery to break atmospheric nitrogen’s triple bond; plants do not. A symbiotic relationship emerged [105]: bacteria turn atmospheric nitrogen into forms that plants can use, while plants repay their bacterial partners with sugars produced through photosynthesis.

And then in the early 1900s, we added a new parameter: the industrial machinery to break atmospheric nitrogen’s triple bond. We could make ammonia (NH3) from air.

As of 2024, the global ammonia market is worth $80 billion [106]; 70% of ammonia is used on synthetic nitrogen fertilizers [107]. Ammonia is the second-most produced chemical in the world (second to sulfuric acid, another chemical used for fertilizer production among other industrial applications) and emits 1-2% of global greenhouse gas emissions [108].

Instead of bacterial enzymes breaking down the N2 triple bond, and water donating the hydrogens (H), industrial nitrogen-fixation uses heat, pressure and a catalyst to break the triple bond and re-combine it with hydrogens (H) that come from fossil fuels.

Fossil-fuels are a key ‘feedstock’ for ammonia production, with natural gas (72% of global cases) and coal (22% global) providing the majority of the raw materials for the chemical transformation to ammonia [109]. Resultantly, the price of ammonia is subjected to the same volatility as the price of fossil fuels.

The USA is the third-largest producer of ammonia after China and Russia [110]. This is not surprising as the USA and Russia are the top two natural gas producers in the world [111] and China is the largest coal-producing country (almost 5 times the production than the next largest producer, India) [112] with the majority (82%) of their ammonia production relying on coal feedstock [113,114].

Fossil fuels are a reagent in the reaction to form ammonia, and are also used to generate the high heat and pressure environment required for the reaction, and the electricity to power the machinery.

“Natural gas accounts for 72-85% of the ammonia production cost” and the “increases in ammonia prices [are] paid by farmers” [115].

Additionally, synthesizing ammonia is the most energy and resource-intensive step in the production of fertilizers, accounting for 80% of fertilizer’s energy consumption [116].

Overall, ammonia production is deeply intertwined with the economics, geopolitics, and supply chains of fossil fuels.

A Closer Look into Ammonia

As ammonia (NH3) is a highly toxic and flammable gas [117], in the industrial world it is often converted to derivatives that are liquid or solid, safer to transport and store, and are easier to handle than gaseous ammonia. The major derivatives are urea (CH4N2O), ammonium nitrate (NH4NO3) and nitric acid (HNO3), “which carry 55%, 26% and 13%, respectively, of the current global synthetic nitrogen fertilizers and facilitate the transport of ammonia” [118].

Ammonia plants are large and centralized to achieve economies of scale, reducing the already-high costs associated with the energy-intensive Haber-Bosch process. They are often located near natural gas or coal sources to ensure a stable supply of feedstock.

The process of an ammonia plant has five components: (1) hydrogen source, (2) nitrogen source, (3) Haber Bosch, (4) condenser, and (5) continual recycling [119].

Starting with (1), feedstock solution, such as natural gas, is processed to isolate hydrogens. 72% of hydrogen is manufactured from steam methane reforming (SMR), a process that uses high-temperature steam to react with natural gas (methane) to produce hydrogen gas (H2) [120,121]. For coal feedstock, a process called coal gasification converts coal into syngas (a mix of hydrogen, carbon monoxide, and carbon dioxide), which is cleaned, shifted, and purified to produce hydrogen gas (H2) [122].

Then, step (2) gathers nitrogen gas (N2) from the air via cryogenic distillation, essentially cooling air to extremely low temperatures to separate its components by exploiting their different boiling points.

In step (3), the inputs from (1) and (2) are combined at a 3:1 ratio of H2 and N2 respectively, in a high heat (400–450 °C), high pressure (150–250 bar) and iron-catalyzed environment, called the Haber-Bosch process [123].

Next (4), ammonia is separated by condensation (cooling down) and collected as a liquid.

Unreacted gasses are recycled in (5) to go through (3) and (4) again [124].

Overall, the world has about 550 ammonia plants [125]. With ~8 billion humans on earth today and 50% of food supply reliant on synthetic fertilizer, and ~70% of ammonia going towards fertilizer use, each ammonia plant on average supports the food supply for ~10.4 million people [126]. It is a highly centralized system!

“Even though some ammonia producers advocate for distributed production of ammonia in small ammonia plants, most companies prefer to build large facilities near cheap raw material sources and transport the product by ship, rail, or pipeline to the consumers” [127]. Modular production may enable future flexibility and shorter production to consumption loops for nitrogen fertilizer, in addition to being more resilient to volatile spikes of fossil fuel production.

Four technology licensors dominate the ammonia production market: KBR, Haldor Topsoe, ThyssenKrupp Industrial Solutions, and Casale. [128]. KBR, for instance, holds approximately 50% of the licensed capacity in the global ammonia market, having been involved in the licensing, engineering, or construction of over 250 grassroots ammonia plants worldwide since 1943 [129]. Similarly, Haldor Topsoe has built 60 ammonia plants since 2000 and supplies catalysts to 248 plants globally, representing a significant share of the market [130]. hyssenkrupp, through its subsidiary Uhde, is recognized as a world leader in alkaline water electrolysis and has a substantial presence in ammonia technology [131]. These companies most people have never heard of underpin the complex web of ammonia production infrastructure. They invisibly support agriculture; their work demonstrates the often-underappreciated importance of the technological layers that enable societal infrastructure.

“The production of nitrogen fertilizers involves complex supply chains with long-distance transport costs” [132]. Ammonia (NH3) and its derivatives: urea (CH4N2O), ammonium nitrate (NH4NO3) and nitric acid (HNO3), are often transported far from their production sites to where they will be consumed. For instance, in the United States, production happens in places with large amounts of natural gas feedstock, like Texas, but the end products are ultimately consumed in places like the US Mid-West that require nitrogen fertilizer.

Ammonia is “almost always transported in the liquid state” and therefore must be compressed, refrigerated or some combination, to keep it as a liquid. Liquid ammonia is transported by a variety of methods including ships, barges, railcars, trucks, pipelines and more, with ocean shipping being the most common [133]. In addition to ammonia, a significant portion of nitrogen fertilizers is transported in the form of urea, which is safer and easier to handle due to its solid form. Unlike ammonia, urea does not require specialized pressurized tanks, making it more versatile for storage and transportation across long distances. The stability and high nitrogen content of urea make it one of the most widely traded nitrogen fertilizers globally, especially in regions where liquid ammonia infrastructure is limited.

Mining for P

Phosphorus, another essential plant macronutrient, cannot be fixed from air. It is mined from phosphate rock, a finite resource which may be at risk for depletion within the century [134]. 90% of global phosphorus demand is for food production [135]. As agriculture intensifies to meet global food demand, efficient phosphorus use is vital, but limited reserves and environmental impacts from mining and runoff pose challenges.

The geographic spread of phosphate reserves is highly concentrated in Morocco which holds 70% of global supply, followed by China at 6% [136]. A portion of Morocco’s phosphate is in Western Sahara, a disputed territory in northwest Africa.

A quote from an Atlantic article on this issue demonstrates how important these phosphate reserves are to local authorities: “ “I've been to 70 countries, including Iraq under Saddam and Indonesia under Suharto,” says Stephen Zunes, an international-studies professor at the University of San Francisco. “[Western Sahara] is the worst police state that I’ve ever seen”” [137].

As there is no replacement for phosphate in agriculture [138], much of the world’s food supply may rely on Morocco’s trades. To keep their geographic monopoly, “Morocco, for their part, has been denying Western Saharan independence with growing vigor” [139].

According to the Office Chérifien des Phosphates (OCP), phosphates are considered Morocco's equivalent of oil, underscoring their critical economic importance [140]. Humans build transportation infrastructure when we have important things to move and trade; along those lines, the world’s longest conveyor belt system, goes from the Bou Craa phosphate mine to the coastal town of El Marsa 61 miles out [141]. From the coast, phosphate goes on a global cruise to farms around the world.

With a shrinking global phosphorus supply, recycling phosphorus from wastewater is crucial because nearly 100% of the phosphorus consumed by humans is excreted through urine and feces. Overall, there is an 80% loss from mine to fork [142].

By reducing excess phosphorus application, we can reduce reliance on finite phosphate rock reserves and promote a circular nutrient cycle. Moreover, implementing phosphorus recovery from wastewater not only helps conserve this vital resource but also mitigates the environmental risks associated with excessive phosphorus runoff, such as harmful algal blooms [143].

The following figures demonstrate the import and export behaviours of countries around the world [144].

In conclusion, phosphorus is indispensable for modern agriculture, yet its finite nature and uneven global distribution present significant challenges. The concentration of phosphate reserves in politically sensitive regions, such as Morocco and the disputed territory of Western Sahara, raises concerns about the stability and sustainability of phosphorus supplies. To address these issues, it is crucial to adopt strategies that enhance phosphorus use efficiency and promote recycling.

Mining for K

A quick Google search for potassium will yield many pictures of Bananas. I think this is incredible, as potassium in its purest form is violently reactive, spontaneously exploding in the presence of water or air. This transformation—from an explosive metal to a non-explosive component of a tropical fruit— highlights the incredible versatility of chemistry. The exact same atomic and subatomic structure behaves in drastically different ways across contexts.

What seems to be a diametrically opposed comparison (metal vs. banana), is actually a deeply intertwined relationship. The potassium in your banana likely began its journey deep underground, extracted as potash from vast mineral deposits. This raw material, mined in countries like Canada, Russia, and Belarus, is refined and processed into fertilizers that replenish soils depleted by continuous farming. Without this extraction and distribution network, crops like bananas, which depend on potassium for growth, yield, and quality, could not thrive at the scale required to feed a global population. This intricate link between mining and food production underscores how industrial processes sustain agricultural abundance. It also reminds us that the food on our plates relies not only on farmers but also on engineers, chemists, and miners working behind the scenes to extract and supply the essential elements of life.

Industrially, potassium begins its journey not in its metallic form but as part of naturally occurring salts found deep within the Earth's crust. These potassium salts, such as sylvinite [145,146], are better known as potash, a term that dates to when wood ash was leached with water and evaporated to create potassium carbonate (K2CO3) [147]. Today, potash refers to mined potassium-rich minerals that serve as a cornerstone of modern agriculture. 95% of Canada’s potash is used for fertilizers [148].

The story of potash is one of recycling and chemical engineering. “Potassium and calcium are essential for tree metabolism and various physiological processes related to growth” [149].

We used to use tree wood as a source of potassium. First, we burned the wood. Extracting potassium directly from unburned wood would be inefficient due to the small amounts of potassium relative to the large volume of organic material. However, burning the wood releases its volatile parts (e.g., organic compounds, tar, moisture) and leaves behind the non-volatile parts in the ash [150] (e.g., potassium carbonate (K2CO3), Potassium chloride (KCl), Potassium sulfate (K₂SO₄)) [151].

The ash is then put in a pot. Potassium salts are water-soluble; placing the ash in water separates the potassium salts from insoluble ash residue. The filtered potassium-salt-water-mixture is called lye. The lye is then boiled to evaporate water, leaving behind the dissolved potassium salts [153]. Hence the name potash, the elemental name potassium, and the symbol K which comes from the Latin word Kalium, meaning “plant ashes” [154].

Given that hardwood was the primary input, it is no surprise that areas with a lot of timber (e.g., Canada) were the largest producers of potash. However, in the mid-19th century, the first mineral potash deposits were discovered in modern day Saxony-Anhalt, Germany [155]. Ash-to-pot forms of potash production were disrupted by mining: “Potash mining had the clear advantage of being implementable on very large industrial scales, a concept acclaimed by the tycoons of the industrial revolution. Furthermore, the high K₂O content in the final product allowed a significant reduction in transportation cost” [156].

Potash mining gained prominence during the Industrial Revolution due to its scalability and efficiency, aligning with the era's focus on large-scale industrial processes and cost-effective resource extraction, particularly in reducing logistical expenses through higher purity outputs. Additionally, with the industrial revolution’s development of larger-scale transit systems like railways, it was much easier to transport bulk items like lumber or mineral potash. This infrastructure not only increased the profitability of mining but also made the trade of high-demand materials such as lumber far more lucrative than ashes, as wood could now be directly marketed as construction material or fuel [157].

The industrial revolution created a mutually amplifying cycle of innovation: advances in industrial-scale mining and production fueled demand for improved transportation systems like railways, which in turn opened new possibilities for the extraction, trade, and profitability of raw materials, driving even further technological and economic growth.

Another example of a positive feedback loop driven by industrialization: “Fortunately, in 1943, a large deposit of potash (salt) was discovered in Saskatchewan in the process of drilling for oil. Today, Canada is once again the world’s largest potash exporter, accounting for 43% of world trade. Canada exports potash to over 40 countries” [158]. In the search for a key energy source, we found a key agricultural resource; exploration can yield unintended, exciting discoveries [159]. Since the discovery, Canada has become the largest potash producer in the world (28.6%), followed by Russia (17.9%), Belarus (16.9%), and China (13.1%) [160]. The figure below highlights the “basins” (deposits of Potash), around the world [161].

Potash deposits are formed over millions of years as ancient seabeds evaporated, leaving behind layers of mineral-rich sediment. These deposits, embedded in rocks and clay, are often located thousands of feet below the surface, requiring extensive mining and processing to extract. The process is both labor-intensive and technologically sophisticated, involving either traditional shaft mining [162] or solution mining, where water is injected underground [163] to dissolve the salts, which are then pumped to the surface for refinement [164].

Most mining is done by traditional shaft methods [165]. In 2013, 5 of the 6 mines Potash Corp operated in Canada used conventional mining methods [166]. Conventional underground mining is advantageous for potash extraction when deposits are relatively shallow, geologically stable, and economically viable, allowing for efficient and safe resource recovery. On the other hand, solution mining is increasingly utilized when potash deposits are deeper, less geologically stable, or located in regions where conventional mining would be cost-prohibitive or unsafe. Solution mining involves injecting water into underground potash deposits to dissolve the salts, creating a mineral-rich solution called brine that is then pumped to the surface for processing.

The first figure below overlays potash mines on the Elk Basin potash deposit in Saskatchewan [167]. Notably, a majority of them are conventional mines. The second figure details the type of mining that may be most appropriate in each region of the basin [168]. Most of the mines lie in the “conventional mining” region towards the north of the deposit, which are the shallowest and most economically viable to mine.

Similar to the traditional process of potash production, solutions mining exploits the solubility and then non-volatility of potassium ionic compounds. Essentially, when hot water is pumped into the deposit, the potassium dissolves; that hot water can be pumped back up to the surface where the water can be evaporated out, leaving the salt. The water is hot because hot water dissolves minerals more efficiently [169]. Therefore, less water is required to dissolve the minerals, which reduces the cost pump the water back to the surface [170]. Solution mining can also be done on the remnants from conventional mining once exhausted, or to remove lower-grade salt [171]. Belle Plaine Potash Mine was the first solutions mine, and still the world’s largest, pictured below:

The Belle Plaine facility, located between Moose Jaw and Regina in Saskatchewan, is recognized as the world's first and largest potash solution mine. Operated by The Mosaic Company, this facility employs a solution mining process injected over 1 km below the surface to dissolve potash deposits. Mosaic also operates Esterhazy K3 mine, the largest potash mine in 2024. K3’s produces 8 million tonnes annually —surpassing the total potash output of Russia, the world’s second-largest potash-producing country, which produces 6.5 million tonnes in total [174].

Most of the major potash solution mining companies are in Saskatchewan, Canada [175]. Three of the largest are: Mosaic, Potash Corporation of Saskatchewan (now Nutrien), and K+S Potash Canada. Mining is energy-intensive (takes a lot to pump water 1km from underground!), and in Canada, the major sources of energy for potash production were natural gas (77%) and electricity (20%)— “Natural gas is used for mine air heating, building heating, steam generation and product drying. Electricity is used for powering mining machines, hoisting, conveying, ventilation, lighting, dewatering, mill operations, tailings management and office/administration facilities” [176]. The energy demands underscore the logistical and operational challenges that make Saskatchewan's potash mining industry a feat of engineering and resource coordination. The high concentration in both geography and operators underscore the social and economic responsibility in the hands of my home country, Canada.

Potash production would be incomplete without the mention of Nutrien, the world’s largest Potash producer at 20% market share [177,178]. The formation of Nutrien in 2018 was the result of a transformative merger between two Canadian agricultural giants: Agrium Inc. and the Potash Corporation of Saskatchewan Inc. (PotashCorp). Agrium had a retail network while Potash Corporation had the fertilizer production capabilities, together, they had a much more vertically integrated business [179]. Hence, the newly formed Nutrien could leverage economies of scale, optimize logistics, and reduce costs, enhancing profitability and competitiveness.

One last important corporate player in the potash industry is Canpotex. Established in 1972, it is a joint venture among Canadian potash producers Nutrien and Mosaic, serving as a centralized marketing and distribution entity for potash exports outside of Canada and the United States. Operating as a legal cartel [180], Canpotex allocates market shares to its members based on their production capacities, enabling coordinated sales strategies and optimized global distribution. This structure enhances market resilience by allowing Canpotex to effectively manage supply disruptions, such as those caused by mine disasters, thereby stabilizing prices, and ensuring consistent supply to international markets. By consolidating export operations, Canpotex leverages economies of scale, strengthens bargaining power, and maintains a competitive position in the global potash industry [181].

Overall, potassium is a fantastic tool for the food system and its application should be encouraged by farmers: “None of the forms of [potash] provide any harmful effects, unless, like any substance, they are used in excess” [182]. The figure below demonstrates the uneven application of Potash worldwide, particularly, the deficit in Africa.

The intricate process to extract K—from ancient geological formations to industrial extraction and agricultural application—demonstrates the complex interplay between natural resources and modern food systems. It is a hidden but essential connection that underpins the bananas in our fruit bowls and the cereals on our breakfast tables, highlighting how deeply intertwined mining and food production truly are.

The Big Picture: Modern NPK Fertilizers as Societal Infrastructure

The map above highlights the clustered North American fertilizer production network.

Nitrogen production is heavily concentrated in the Midwest and Gulf Coast regions, leveraging proximity to natural gas supplies—a critical input for ammonia synthesis—and close ties to key agricultural zones. Phosphate production, on the other hand, is centralized in Florida due to its phosphate rock reserves, while potash production is almost entirely situated in Saskatchewan, Canada, reflecting the province's dominance in global potash reserves.

This geographic clustering ensures efficient access to raw materials and aligns production with high-demand agricultural areas, such as the Midwest. The rail network plays a vital role in bridging production sites with agricultural regions across North America. Fertilizers, being heavy and bulky, rely on these rail systems for cost-effective long-distance transportation, ensuring timely delivery to farmers. This interconnected system of resource extraction, industrial production, and transportation highlights the critical infrastructure that supports North America’s agricultural productivity. However, one input we cannot overstate the importance of is energy.

If we think of technology as the application of scientific knowledge, its fundamental purpose is to perform or enable work (‘the application’). Energy is the ability to do work [183]. Therefore, energy access is central to technological development because it is an essential input. Technology, in turn, amplifies collective leverage, allowing populations of people to achieve far more than the sum of their parts. Abundant energy, first coal then oil, unlocked the technologies and the Industrial Revolutions that followed.

For instance, energy was the precursor to Iron or Steel [184]. These materials, and the energy it took to produce them, were essential for development. Likewise, abundant energy is critical to modern technologies, like ammonia production, potassium mining, AI, data centers, desalination plants, etc [185]. Energy remains the root of innovation: it determines the pace and feasibility of advancements, whether in the Industrial Revolution’s factories or the modern world’s interconnected and resource-demanding systems.

The production of NPK fertilizers is inherently energy intensive. Nitrogen fertilizer production, in particular ammonia, requires energy to power the high-heat, high-pressure environment for synthesis, as well as natural gas as a main reactant. In addition, mining of P or K requires substantial energy to operate the mining machinery. Once produced, NPK fertilizers must be transported to their end users. A 200,000-ton cargo ship sailing halfway across the world, as one could imagine, requires a lot of electricity, fuel, and energy for its machinery or subsequent land-transportation. These substantial energy requirements underscore the critical role of energy access in agricultural productivity. Given that energy is a scarce [186] and geopolitically disputed [187] resource, the down-stream products of energy are subject to international volatility.

In the case of ammonia production, the Russia-Ukraine conflict has disrupted natural gas supplies and globally driven up prices, straining nitrogen fertilizer affordability and supply. For instance, CF Industries Holding Inc, an American fertilizer company, permanently shut down fertilizer operations at one of their UK plants in 2022 due to continuing high natural gas prices [188]. Rising fertilizer costs impact food security by increasing the expenses for crop production worldwide. While alternatives are being explored, natural gas remains the most efficient resource for large-scale nitrogen fertilizer production essential for global agriculture. To that end, the world’s longest ammonia pipeline connects Russia and Ukraine [189].

Through NPK fertilizer we unlocked the potential of our land: “Nearly all commodities in the pre-industrial economy depended on land, and even the processing of minerals and metals relied on wooded areas for fuel. In a preindustrial economy, this limit is expressed most starkly in the food supply, given the restricted capacity of plants to photosynthesize solar energy and draw nutrients from the soil” [190].

Fertilizer and the industrial revolution enabled some of the greatest liberation in human history: they no longer mandated we spend our lives as sustenance agrarians. This unlocked a global marketplace of products, careers, and cities. “International trade also presented options for certain countries to be released from the narrow constraint of their own surface area, through ‘horizontal land expansion’” [191].

As we look to the future, the convergence of advanced technologies and sustainable energy sources holds the promise of further liberating humanity from traditional constraints, paving the way for unprecedented innovation, and staying true to my slavic instincts, feeding everyone.

Future

“Expensive, second-best solutions won’t be adopted by markets, and therefore won’t drive decarbonization” [192].

The future of feeding everyone will be built by competitive technologies.

The Challenge for Fertilizer

“The main challenge for ammonia production is finding an economically viable, energy efficient, and more sustainable pathway for the production of hydrogen” [193].

Natural gas is used two-fold in ammonia synthesis: to power the operation, and as a raw material. The cost-competitive creation of energy alternatives could replace natural gas as a power source (discussed in due time).

For the synthesis of ammonia, natural gas is used for its hydrogens, and therefore, to replace it as a raw material [194] we need to find a different method to produce hydrogens.

Green Hydrogen

“Green Hydrogen” is produced by splitting water into oxygen (O2) and hydrogen (H2) gasses, with electricity, in a process called electrolysis [195]. While technically feasible, green hydrogen remains expensive: “electrolysis for green hydrogen production needs to significantly scale-up and reduce its cost by at least three times over the next decade or two” [196].

Electrolyzers are the devices that power electrolysis, thus, making them cheaper, more efficient, and scalable is a key engineering problem to enable Green Hydrogen. There are multiple new electrolyzer cell designs, one to watch is Solid-oxide electrolysis cells (SOEC) for their potential to recycle waste heat to approach electrical efficiencies of 90-100% [197].

However, 60-70% of the cost of Green Hydrogen comes from electricity [198]. So once again, we need clean, abundant, cheap energy.

Manufacturing Plants

Traditional large-scale ammonia plants rely heavily on centralized infrastructure, and extensive transportation networks.

Modular systems, in contrast, enable localized production closer to the point of use, such as farms or industrial hubs, reducing transportation-related emissions and costs. They also offer flexibility in scaling production to meet regional or seasonal demands, which is crucial for small or remote communities that lack access to centralized supply chains [199].

“The current centralized configuration of the ammonia industry makes the production of nitrogen fertilizers susceptible to the volatility of fossil fuel prices and involves complex supply chains with long-distance transport costs. An alternative consists of on-site decentralized ammonia production using small modular technologies, such as electric Haber–Bosch or electrocatalytic reduction” [200].

Modular ammonia production mirrors the approach seen with nuclear small modular reactors (SMRs), which prioritize localized, scalable solutions to address energy needs more flexibly. This shift also reduces upfront capital expenditures (albeit by potentially sacrificing economies of scale), making modular ammonia production more attractive to investors who might otherwise consider full-size industrial plants too risky due to their high initial costs.

P & K Innovations

Innovations in phosphorus (P) and potassium (K) production are addressing critical challenges of sustainability and supply-chain resilience.

For phosphorus, recycling from waste streams such as animal manure and wastewater through technologies like struvite precipitation is becoming increasingly viable, reducing dependency on finite phosphate rock reserves while mitigating environmental impacts from runoff [201].

Similarly, potassium recovery from unconventional sources, such as seawater and brines, is advancing through techniques like solar evaporation and selective chemical extraction, offering scalable alternatives to traditional potash mining [202].

Innovations in mining technologies, such as solutions mining, AI-driven exploration, autonomous equipment, and real-time monitoring systems, are also transforming the industry by increasing efficiency, reducing costs, and minimizing the ecological footprint of extracting critical nutrients like phosphorus and potassium [203]. These approaches collectively aim to secure critical nutrient supplies.

Precision Agriculture

Precision agriculture leverages advanced technologies, such as GPS, IoT sensors, and AI-driven data analytics, to optimize fertilizer application. By tailoring nutrient delivery to the specific needs of crops and soil conditions, precision agriculture minimizes over-application and reduces nutrient runoff, which can harm ecosystems.

Techniques like variable rate technology (VRT) apply fertilizers at different rates across a field, ensuring that plants receive only what they need [204]. This approach improves yield efficiency, reduces costs for farmers, and supports environmental sustainability by mitigating the impact of excess nutrients on water systems. As these technologies become more affordable and widespread, they promise to transform fertilizer management and enhance global food security.